Discover the future of gripping

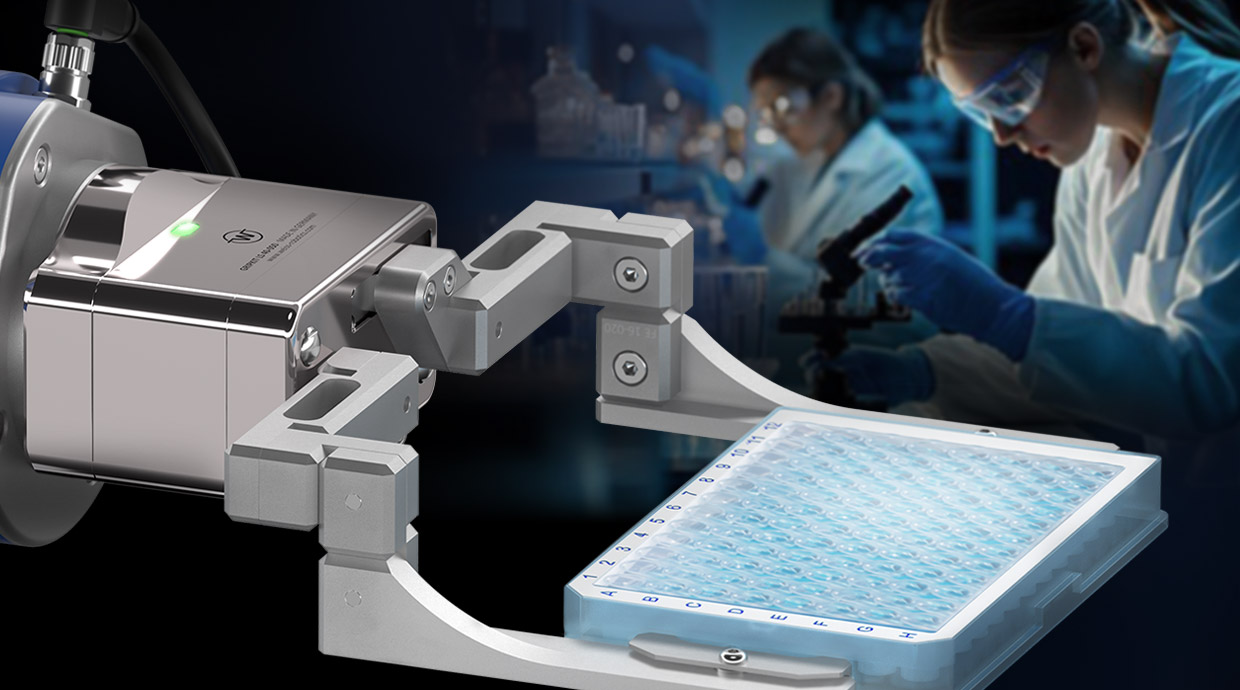

As a leading specialist in mechatronic gripping systems, we have been developing and manufacturing smart servo grippers for the sensitive and precise handling of demanding gripping parts for assembly automation, the electronics and semiconductor industries and the life sciences sector since 2008.

Smart Grippers. Seamlessly Integrated.

At Weiss Robotics, the gripping system doesn’t stop at the robot flange. Our GRIPLINK technology offers a seamless and efficient integration of servo-electric grippers directly into your robotic application — for greater flexibility, easy commissioning, and maximum process reliability. Thanks to standardized interfaces and intuitive control, GRIPLINK® significantly reduces programming efforts and enables quick adaptation to changing production requirements. At the same time, direct communication between the robot and gripper ensures precise movements and reliable process monitoring. But GRIPLINK offers even more: Continuous real-time data collection enables in-depth analysis of gripping processes, supports deep learning applications, and provides valuable insights for process optimization. This creates the foundation for intelligent automation, increasing both efficiency and quality in your production over the long term.

GRIP SMARTER

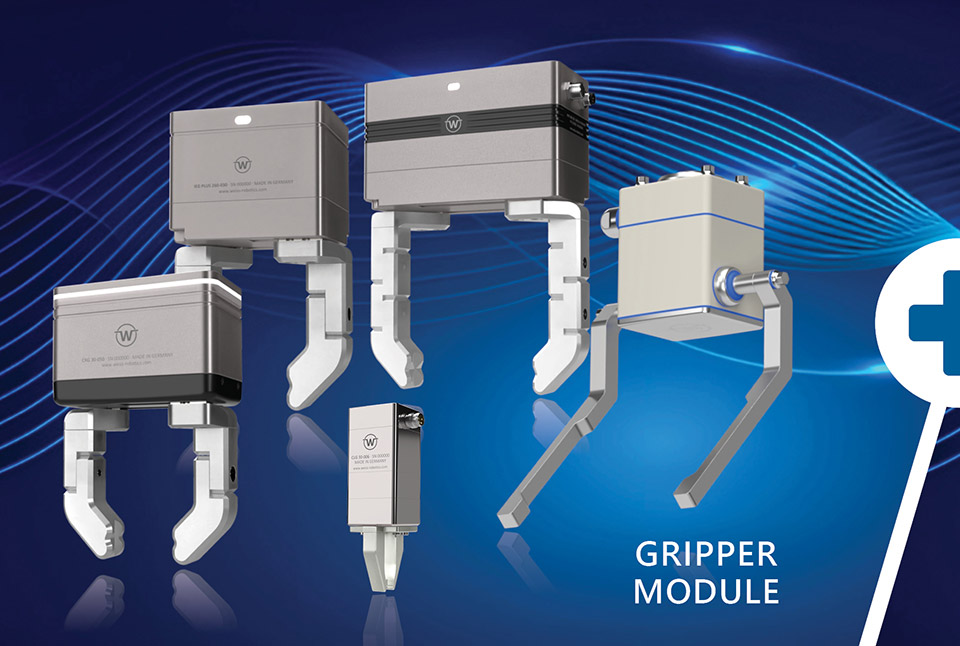

Smart gripping modules from Weiss Robotics with integrated workpiece recognition and grip monitoring optimize your gripping process and increase your productivity.

DIGITAL GRIPPING PROCESS

Gripping modules from Weiss Robotics with direct data connection take your gripping process to the next level. Always have your production under control.

EASY INTEGRATION

Reduce your engineering, assembly and maintenance costs by using smart gripping modules from Weiss Robotics. With integrated diagnostics as standard.

GRIP WITH ADDED VALUE

Extend your technological advantage with intelligent handling solutions from Weiss Robotics.

EXCELLENT CONSULTING

Weiss Robotics is the specialist for mechatronic handling solutions. Benefit from expert advice and first-class support from one specialist to another.

HIGHTECH MADE IN GERMANY

As an owner-managed company, Weiss Robotics develops and manufactures its products in Ludwigsburg, Swabia. Trust in premium quality directly from the manufacturer.

Current highlights

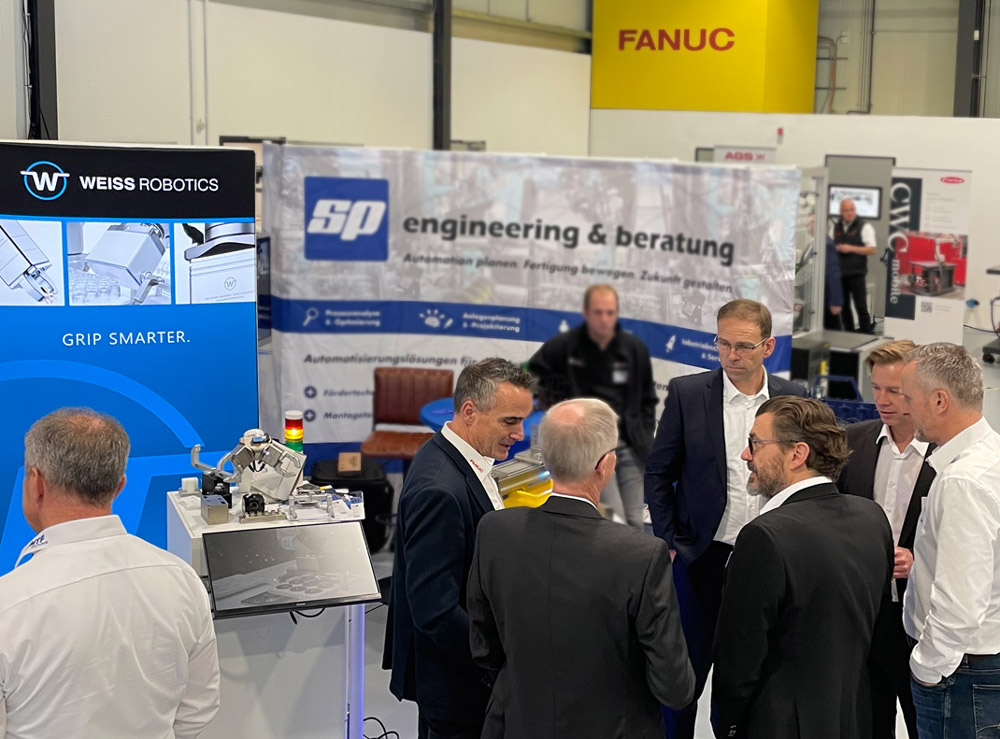

A reason to celebrate: 4 years of FANUC Meinerzhagen

On November 20, 2025, we were once again invited to attend the FANUC Open House in Meinerzhagen – a special event marking the fourth anniversary of the local FANUC branch. Together with FANUC and many other partners from the automation industry, the day was all about innovation, exchange, and practical applications.

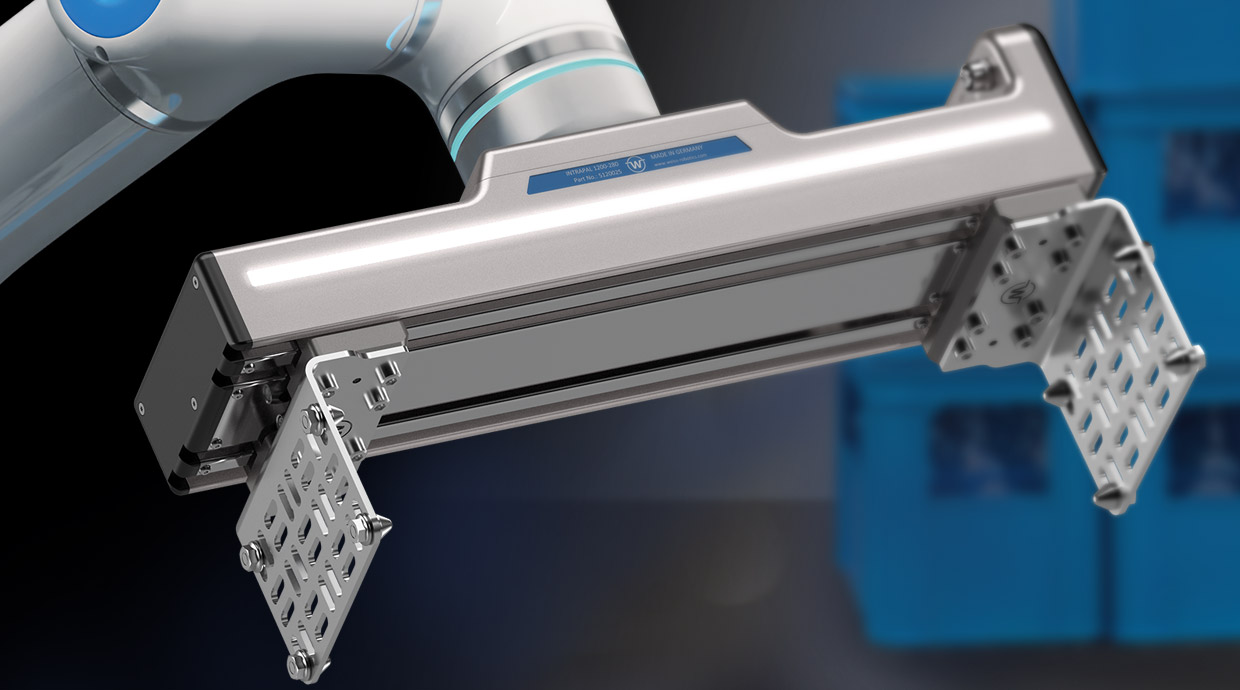

A special highlight at our booth was the demonstration of the new INTRAPAL gripper, the smart gripping solution for intralogistics. Many of the discussions focused on specific application scenarios, efficient handling solutions, and the question of how modern gripping technology can be optimally integrated into automated processes.

The event was rounded off by a subsequent exchange in a relaxed atmosphere – including cool drinks.

A big thank you to FANUC Germany for the excellent organization and to all visitors for their great interest and the inspiring conversations.

Read more … A reason to celebrate: 4 years of FANUC Meinerzhagen

Nationale Cobotdag 2025 – a strong signal for the future of manufacturing

On November 19, 2025, the National Cobotdag 2025 took place in Tiel (Netherlands) – an outstanding event focusing on collaborative robotics. Weiss Robotics was pleased to be part of it and, together with numerous innovative companies, was able to send a strong signal for the Netherlands as a manufacturing location.

At our booth, we showcased, among other highlights, our new INTRAPAL gripper, which attracted great interest thanks to its intelligent technology and high precision. Direct exchanges with experts from various industries confirmed once again the enormous potential of smart gripping solutions in modern manufacturing.

We would like to sincerely thank the organizers and everyone who visited us on site – it was an inspiring day full of valuable conversations and fresh impulses.

See you next time – we’re already looking forward to Nationale Cobotdag 2026!

Read more … Nationale Cobotdag 2025 – a strong signal for the future of manufacturing

Teamwork with a height advantage: INTRAPAL meets lifting column

From November 3 to 5, 2025, our INTRAPAL gripper was presented at the trade fair for mechanical engineering – at the booth of our partner Columbus McKinnon Engineered Products GmbH.

A particular highlight of the presentation was the combination of the gripper with a lifting column, which provides significantly greater flexibility and reach. This solution shows how a robot's capabilities can be expanded when it is required to perform tasks outside its normal working range – for example, in applications where additional lifting height is required. This solution impressively demonstrates how the intelligent combination of components can expand the possible applications of industrial robotics.

Visitors to the trade fair showed great interest in this versatile solution, which makes an important contribution to greater efficiency and adaptability in automation.

We would like to thank our partner Columbus McKinnon for the successful joint presentation.

Read more … Teamwork with a height advantage: INTRAPAL meets lifting column

Product catalog

Discover our wide range of products! Download our current product catalog to get a comprehensive overview of our range.